Material Hoist

Material Hoist

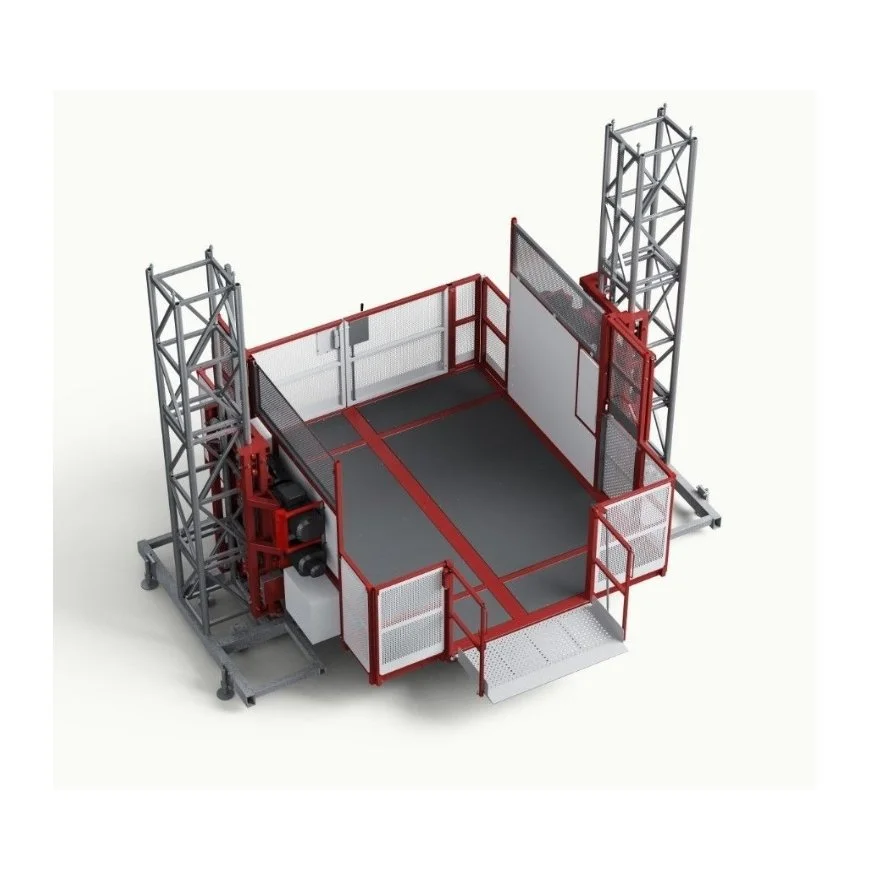

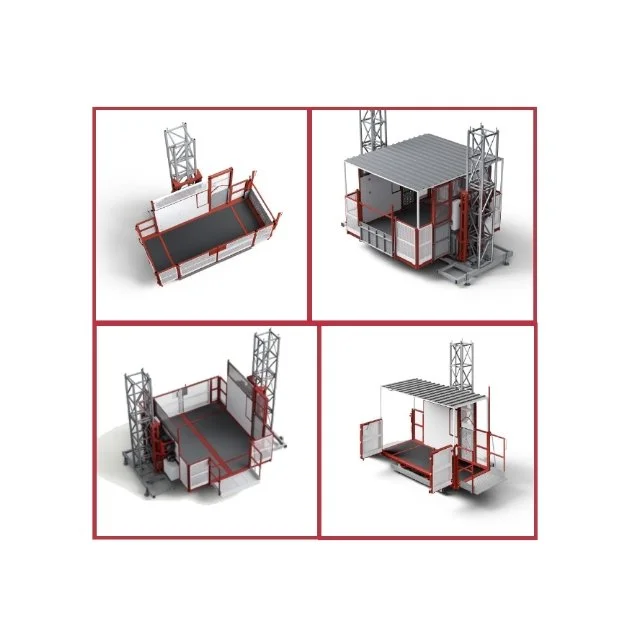

Our Automated Materials Hoists allow contractors to load up buildings very affordably. No operators are needed. These function just like an automated interior elevator. Select the floor. Send it up. It stops at the floor. Or call it to yourself at the floor with buttons there. It couldn’t be easier. The requirement to supply subs with hoisting is satisfied with these and you don’t have a monthly cost associated. Between a 3rd party operator and a hoist, It’s pretty easy to edge on $30,000 a month for a comparable solution. We’ll just sell you the solution. Pay once and run it as long as you like. Let’s take a look. Here’s a Brochure on the Transport Platforms too.

Dimensions and Load Capacity

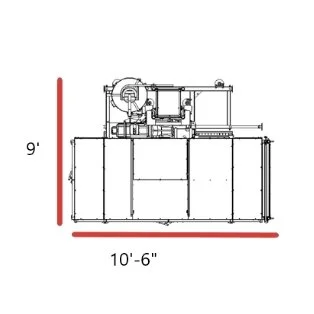

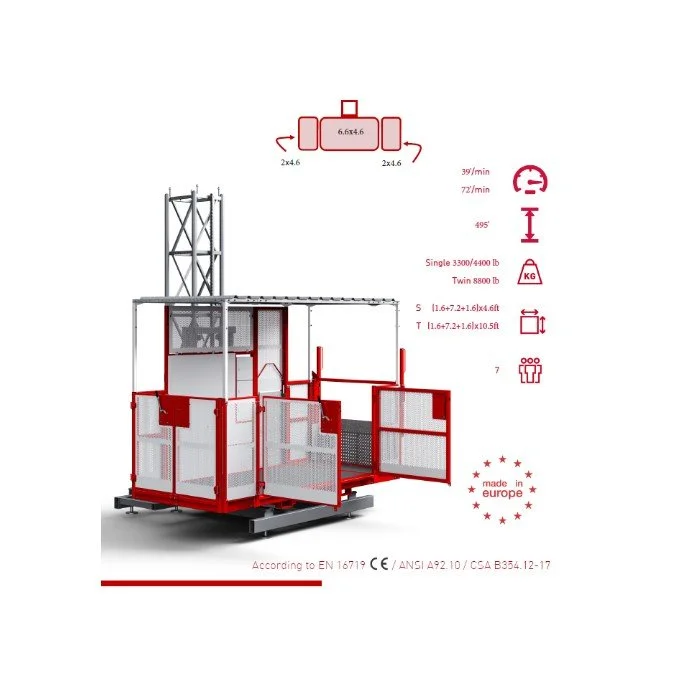

These cars are 4.6 by 10.5’. Those 10 long heavy loads work. You might have to size your drywall down to 10’ from the 12’ selections. We can go to 13’ long cars, but we need heavier towers. If you want to do that, reach out at sales@cranegear.net and we can get a quote going for that.

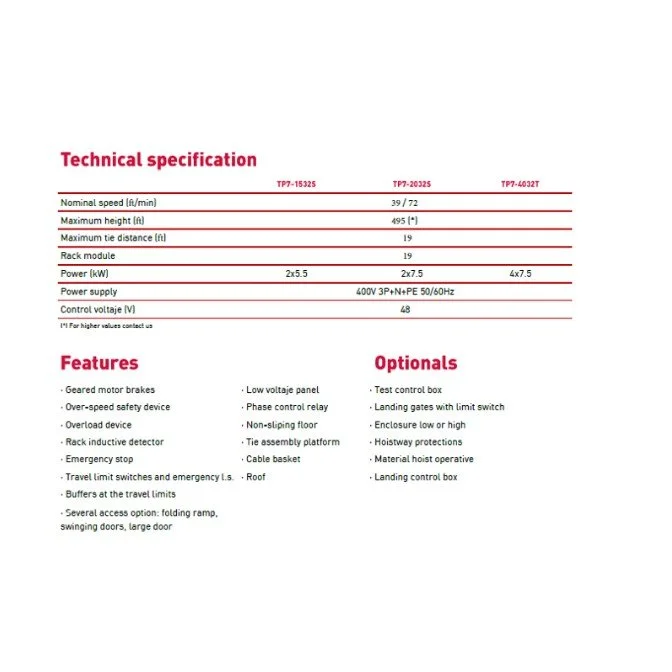

These material hoists are rated at 4400 lbs of load capacity in the Materials Hoist mode. Their speeds are 72’ per minute in this mode. That pallet of paint in five gallon buckets goes from a person carrying it up 5 flights of stairs for 5 hours to one 4 minute load and unload operation. It’s genuinely that stark of a change in operations. Taking construction materials off of the backs of people can be very profitable.

These hoists are technically “Transport Platforms” under the scaffold standard. They are also designed to transport humans. Seven people can ride in these. They are slow in this mode. 39’ per minute. It’s not efficient as a means to go up and down the building. But it is another ingress/egress. It’s also another means to rescue unless the patient is over 10’ tall.

Safety in Design. Safety in Practice

Loading up an Apartment building, like a 5 over 2, typically has 25,000 lbs of construction materials going into each unit. This is often loaded on the backs of workers. We can transfer that load to the gears of a hoist. Those knee, back and shoulder injuries can become wear on the gears. The damage you would have to your drywall that would need repairs can become paint touch ups between the jobs on the material hoist. Instead of having ten people on site to unload the cabinet trucks, you have four. Two on the building and two in the truck. Instead of flying them in a crane in a box with fall exposures and crane costs, you have the hoist on site already and the subcontractor does the work with some simple training.

The cost and safety benefits of an automated hoist cannot be overstated. You’ll wonder how you got along without one before. My first hoists that I rented to contractors were small at 6’ by 4’ and rated at 2200 lbs. People would complain about the size when we delivered them. Then 4 month rentals would turn into 9 month rentals. And everyone would complain as we dismantled them so the building could wrap up. If you are building a multi floor project and you haven’t used an automated hoist, you should take a moment to account for how much time you are spending between structure and appliances on getting items into the building. We can turn that into a near zero number so you can focus on the delivery to your client on time and better than they expect.

Built to Scaffold Standards

These hoists have safety built in beyond conventional hoists. These meet the ANSI A92.10 for scaffold. It’s technically a Scaffold Hoist despite the usage of “Material Hoist”. Today’s Transport Platforms have enough safety built in that they can be automated. Additionally, unless your specific location addresses Transport Platforms, you should be able to assemble and use these without a specific license. We obviously aren’t in every state, county and city. You’ll need to verify this for yourself. But this is not a hoist built under ANSI A10.4 or 10.5. It is not a Construction Hoist or Elevator. If assembled and used according to the manufacturer, you should be in compliance in most locations.

Let’s put this into perspective as a Materials Hoist. No one is meant to ride this. The reality is that no person should be exposed to any safety issue on them if it’s maintained. When they stop, they have 150% of the brake capacity and a load cell in them. No hoist should really be past 66% of it’s braking capacity at any time. Most humans are well under 5% as added weight. Transport Platforms pose little to no risk to humans when used as a Materials Hoist. Even when they are used as Personnel Hoists, they are under 50% of their capacity before you add in the back up overspeed brake that would engage at 50+ feet per minute. These are factually about as safe as you can make lifting humans.

Engineering for soils and building

Install accordingly and consider the manual instructions.

Ensure safety systems are in place.

Set Load Cell and overload protection.

Drop Test to check overload protection.

Train the users.

Shipping Door to Door

For the price we are showing, we are offering a hoist with an enclosure and 10’ of tower. The shipping included is for a 40 container and tariff and so on. It’s a door to door delivery. The questions here are just down to options and heights.

Options:

Tower height

Tie ins

Gates including heights

Enclosure height

Auto lubrication

Folding out Platform to work on tie ins- bit of awesome

Jib for towers

Options in cables and control boxes.

Check out the video below to see these awesome automated materials hoists in action.

Material Hoist

Our Automated Materials Hoists allow contractors to load up buildings very affordably. No operators are needed. These function just like an automated interior elevator. Select the floor. Send it up. It stops at the floor. Or call it to yourself at the floor with buttons there. It couldn’t be easier. The requirement to supply subs with hoisting is satisfied with these and you don’t have a monthly cost associated. Between a 3rd party operator and a hoist, It’s pretty easy to edge on $30,000 a month for a comparable solution. We’ll just sell you the solution. Pay once and run it as long as you like. Let’s take a look. Here’s a Brochure on the Transport Platforms too.

Dimensions and Load Capacity

These cars are 4.6 by 10.5’. Those 10 long heavy loads work. You might have to size your drywall down to 10’ from the 12’ selections. We can go to 13’ long cars, but we need heavier towers. If you want to do that, reach out at sales@cranegear.net and we can get a quote going for that.

These material hoists are rated at 4400 lbs of load capacity in the Materials Hoist mode. Their speeds are 72’ per minute in this mode. That pallet of paint in five gallon buckets goes from a person carrying it up 5 flights of stairs for 5 hours to one 4 minute load and unload operation. It’s genuinely that stark of a change in operations. Taking construction materials off of the backs of people can be very profitable.

These hoists are technically “Transport Platforms” under the scaffold standard. They are also designed to transport humans. Seven people can ride in these. They are slow in this mode. 39’ per minute. It’s not efficient as a means to go up and down the building. But it is another ingress/egress. It’s also another means to rescue unless the patient is over 10’ tall.

Safety in Design. Safety in Practice

Loading up an Apartment building, like a 5 over 2, typically has 25,000 lbs of construction materials going into each unit. This is often loaded on the backs of workers. We can transfer that load to the gears of a hoist. Those knee, back and shoulder injuries can become wear on the gears. The damage you would have to your drywall that would need repairs can become paint touch ups between the jobs on the material hoist. Instead of having ten people on site to unload the cabinet trucks, you have four. Two on the building and two in the truck. Instead of flying them in a crane in a box with fall exposures and crane costs, you have the hoist on site already and the subcontractor does the work with some simple training.

The cost and safety benefits of an automated hoist cannot be overstated. You’ll wonder how you got along without one before. My first hoists that I rented to contractors were small at 6’ by 4’ and rated at 2200 lbs. People would complain about the size when we delivered them. Then 4 month rentals would turn into 9 month rentals. And everyone would complain as we dismantled them so the building could wrap up. If you are building a multi floor project and you haven’t used an automated hoist, you should take a moment to account for how much time you are spending between structure and appliances on getting items into the building. We can turn that into a near zero number so you can focus on the delivery to your client on time and better than they expect.

Built to Scaffold Standards

These hoists have safety built in beyond conventional hoists. These meet the ANSI A92.10 for scaffold. It’s technically a Scaffold Hoist despite the usage of “Material Hoist”. Today’s Transport Platforms have enough safety built in that they can be automated. Additionally, unless your specific location addresses Transport Platforms, you should be able to assemble and use these without a specific license. We obviously aren’t in every state, county and city. You’ll need to verify this for yourself. But this is not a hoist built under ANSI A10.4 or 10.5. It is not a Construction Hoist or Elevator. If assembled and used according to the manufacturer, you should be in compliance in most locations.

Let’s put this into perspective as a Materials Hoist. No one is meant to ride this. The reality is that no person should be exposed to any safety issue on them if it’s maintained. When they stop, they have 150% of the brake capacity and a load cell in them. No hoist should really be past 66% of it’s braking capacity at any time. Most humans are well under 5% as added weight. Transport Platforms pose little to no risk to humans when used as a Materials Hoist. Even when they are used as Personnel Hoists, they are under 50% of their capacity before you add in the back up overspeed brake that would engage at 50+ feet per minute. These are factually about as safe as you can make lifting humans.

Engineering for soils and building

Install accordingly and consider the manual instructions.

Ensure safety systems are in place.

Set Load Cell and overload protection.

Drop Test to check overload protection.

Train the users.

Shipping Door to Door

For the price we are showing, we are offering a hoist with an enclosure and 10’ of tower. The shipping included is for a 40 container and tariff and so on. It’s a door to door delivery. The questions here are just down to options and heights.

Options:

Tower height

Tie ins

Gates including heights

Enclosure height

Auto lubrication

Folding out Platform to work on tie ins- bit of awesome

Jib for towers

Options in cables and control boxes.

Check out the video below to see these awesome automated materials hoists in action.

Transport platform considerations

What is a material hoist used for?

Materials Hosts move heavy loads of construction materials up and down a building while it’s under construction. They are also excellent for waste removal and as a secondary Egress or means of Rescue when sourced as a Transport Platform.

What kind of material hoist do I need?

We believe an automated material hoist is the safest option. If rated at 4400 lbs for heavy loads, they can move most common construction materials. At 10 to 13’ long, most items also can fit inside of them. Removing the people from the hoist operation is the advantage we appreciate the most.

Can a material hoist be used to carry people?

A materials hoist manufactured under ANSI A10.5 should not be used to transport people. Transport Platforms have a Materials Hoist mode. They can sometimes be used as both a personnel and a materials hoist by switching the controls which changes the operations. These must be manufactured under the scaffold code in ANSI A92.10.