Crane Materials Baskets vs Unrated Lifters

Are Your Rigging Crews Undermining Your Crane Safety Program?

An issue that affects at least 90% of the jobsites in the US and Canada is the weak link of what you are lifting. Contractors and regulators put all of this effort into providing a job with planning that ensures safety. For Example:

Soil bearing pressures. A crane that overloads the soils is no bueno.

Inspect the crane before it arrives, and after it’s assembled.

Load test to the rating of the crane for the configuration

Certified operator

Certified rigger

Ensure rope certs are good.

If tower crane, Structural Engineer stamps the base.

All of the rigging is inspected, listed, and rated.

And so on

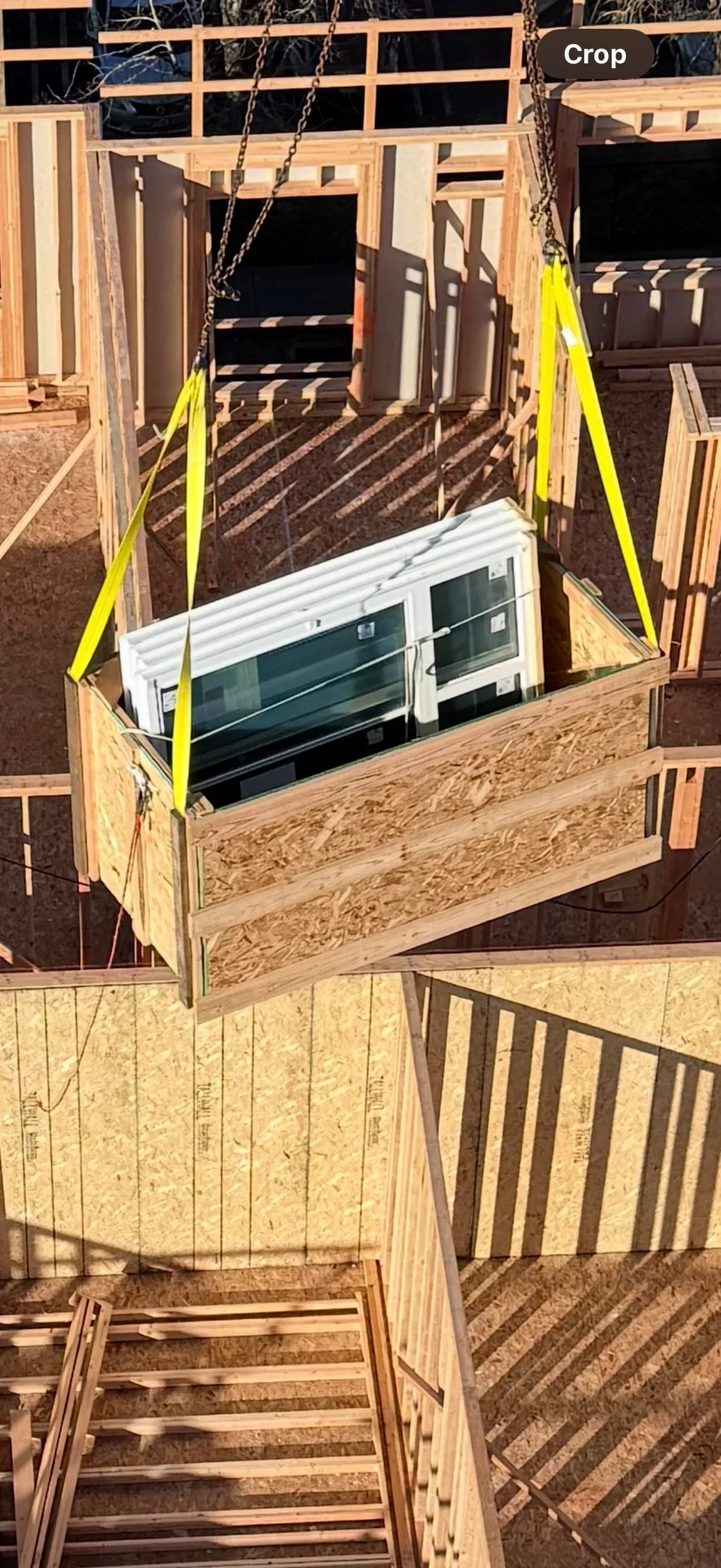

The Unseen Dangers

Then what do your subcontractors do? They send out their tools and product in items that are unsafe to lift. They have no ratings. Can the box support the load? Don’t know. Will the nails in the pallet hold together? Don’t know. What’s the capacity of plastic in 20 degree temperatures? Don’t know. In 115 degree temps? Don’t know. Contractors spend all of this time and money making sure a crane is safe. Then they lift a box that is rated for zero lbs with unknown thousands of pounds in it. It’s the craziest thing. You’ve seen it. Here are some examples.

You can see the pallet failing.

I wish that I could say this is the first OSB box I have seen doing this. It’s not.

Another example of a similar practice.

Rigging on this ready to fly. It’s rated for a forklift. No Crane Ratings.

Consistency of Crane Ratings and Crane Materials Bins

OSHA has been straightforward on this topic since 1969 when the rules were being gathered. 1926.251 addresses Materials Handling. Employers Must ensure:

Tags prescribed by the manufacturer to recommend Safe Working Load.

Not be loaded in excess of its recommended SWL - by the manufacturer.

No used without tag.

Custom designs or other lifting accessories shall be marked and proof tested to 125%.

One can show up here and see my pictured examples and read this code and think, the box is the load and the sling is the tagged part. Let’s do a mental exercise for illustration purposes. If I made the box out of cheese, would a sling under it make it safe to put a 2000 lbs in it? Fortunately, this doesn’t have to be the end of the argument on the topic. We have something more substantial than relying on an argument. OSHA answers questions employers put forth on a topic and they publish the answers. 1926.251 is addressed multiply. You can find the letters here.

In 2004 Moser asked about the applicability of ASME B30.20 to 1926.251 (a)(4). This can only apply to the lifters. ASME B30.20 is for “Below the Hook” lifters. If we were talking about rigging like slings, that would be under ASME B30.9. OSHA and OSHA would note the error in understanding. Instead, they state that following the inspection criteria of ASME B30.20 would be considered as being in compliance with OSHA. So 1926.251 is talking about lifters, and your inspection criteria is to be the same was what you would find in ASME. IE. Tagging, manufacturer, rating, and so on.

Now that you know this detail, how many illegal lifters are on each of your jobsites? How many times have people made an unsafe lift where everyone involved just presumed it was how it was to be done? We’ve normalized risk when it comes to Crane Materials Bins. Everything you do to make the crane safe before the lifter is irrelevant if the lifter containing the goods just falls apart during the lift.

New Regulations Deepen the Dangers

The depth of this unseen danger seems to be bottomless like a Norwegian Fijord. I’m from Washington State. Our crane code section is 243 pages long. If you need to learn a crane code, you’ll need a bowl of popcorn just in scrolling time to find it. But that doesn’t mean it’s as good as the 1969 OSHA rule. Here’s the example of that.

WAC 296-155-56200 says all Structural lifters have to meet ASME B30.20-2021. A cited code and a date. Well, this must be complete and thorough then. But what if it isn’t? The code clearly cites 2021 instead of “ASME B30.20” which would include updates. We have a new ASME as of 2025 that came out before this code was implemented. But the state didn’t adopt it. The new ASME changed something. It adopted “load containers” and defined it. In the past local jurisdictions would conclude that ASME didn’t include “load containers”. There is nothing in the old ASME’s that would exclude them, but that was the common reading. The other reading is that if it didn’t “attach” to the hoist, it didn’t count under ASME B30.20 as a Below the Hook Lifting Device. It’s all reading you want see like a religious argument. But 2025 redefines “load container” and Washington just gets under the law by adopting the 2021 standard specifically. It’s frankly a self-governed state not being as strict as the OSHA Rule I have cited here. Several pages of documents gets around four broad simple sentences in OSHA 1926.251.

If you are in a location under OSHA, or several Canadian provinces, and you don’t have a state agency looking to skirt the rational rule, Here’s exactly what the new ASME of 2025 says about “Structural Lifters”.

Structural and mechanical lifting devices

directly support or contain the load, or include a positive

connection to the load or other component, such as a hook,

or pinned or bolted connection

The new code does not require a positive connection to be a Structural lifter. It’s not “And”, it’s “or”. And anything whose purpose is to “Support or Contain the load” qualifies as a Below the Hook Lifting device. Every one of the pictures I shared above are violations not only of common sense, but violators of legal ways to crane materials. You need a rated crane materials bin. And we can help.

What Do Safe Crane Materials Bins Look Like?

You can spend the world on Crane Bins, or you can get to compliance affordably. Let’s take a look at some options. Sometimes the big spend makes sense and will pay you back. But more often we just need something that we know is good for what we are about to put in it. At the same time, going to a positive connection versus utilizing rigging should return massively in speeding up lift cycles.

1058 Crane Pallet Bin for two Pallets of goods.

This Crane Pallet Bin is on the spendy side of the world. You can get them with a ramp of the gates and lift two pallets at a time. They are rated at 6600 lbs. The functional side of this spend is that you can lift two pallets at a time. So while you’ll spend $3500 and shipping on a Crane Materials Bin like this, it does enable you to lift two pallets at a time. If your crane and people were just $300 an hour, halving the lift cycles starts paying back at $150 per hour. So if you can find 30 hours of use over the 20 years or so that you’ll have it, it pays you back. Or you can build a box and take the time to sling it up every time and risk the lifts?

Crane Materials Bin for full pallets rated at 4400 lbs.

Pallet Sized Crane Materials Bins

Contractors buy plastic bins made for forklifts then use them with cranes. The rating doesn’t carry over. The users have no detail from the manufacturer showing that it was intended to be used as they are with slings on a crane lift. We have a bin that is intended to be used either way, and it’s rated. You’ll stop spending time putting on slings. You’ll stop with the need to buy castors. Let’s suggest that you spend $500 for a plastic bin with the ring for the castors. But then you are putting on the slings every time you want to move it. You spend $1600 on ours, but now you don’t need slings because you just hook in. Can you save $1100 in crane time over 30 years? If the steel version lasts 30 years and the plastic one has been replaced twice by that point, is there any financial benefit to the plastic bin?

You can get our 2031 Crane Materials Bins here. The cost is under $1600 if we sell them from the factory. They do stack up and save space in shipping. The prices shown are “Ala Carte” and as if we are shipping anywhere. Call us for a quote.

Affordable Crane Materials Bins

If we want to get downright affordable without thinking about operational costs, how about our 1311’s. If a Plastic Pallet Bin is $350 dollars without the frame for the castors, how about we beat that. We are at $115 for a steel frame rated at 3300 lbs. They come with four lifting points so your operations side savings is significant. These are great for long items as it is. But what if you want them to have compartments and to be able to carry items too? We can do it with steel sides, mesh, or you can box it in with board holders that we provide. You provide the wood.

1311 with board holders - Crane Rated

1313 that can come with hooks or mast links and compartments. Crane Materials Bin rated at 3300 lbs.

Crane and Forklift Materials Bin

We get creative with our options. Our Stacker Tippers range from $325 to $1035. We do need a frame for lifting them. But then you can quickly grab and move them as well as tip them out safely. And they are rated. When we are talking about $450 per unit, depends on the sizing, it begins to make you wonder why people choose to go with the cheap options like building boxes. Even if you only had an hour in hunting down materials and building a box, the operations costs and rebuilding them every 10 years are going to factor in as well. With steel and ratings, you should have a long service life that pays you back dozens of times with our solutions.

1045 Semi Automatic Crane Materials Bin

Sometimes you’ll see people using boxes for trash. I’ve seen plenty of bins made of wood with slings sandwiched into them. But in the end, the new ASME specifically shows a drawing of a “skip pan”. This picture above is a skip pan. If you ask the Europeans, they’ll call it a boat skip. But they are also Structural Lifters that “contain or support the load”.

We have fully automated crane trash bins and semi automated versions. The fully automated versions are great up to 10.4 yards. The semi-automated versions like this one are best to about 2.6 yards. Beyond that the bale arm takes some side load that makes some crane operators uncomfortable. We are really talking about 100 lbs for the large versions, but visually it’s something people are conditioned away from doing in the training years as a operator. So I would recommend 2.6 yards and below for the Semi Automated versions. If you wanted to go larger, the 1045 Automated Crane Skip Pans are the right choice.

We have more options in Crane Materials Bins and in Structural Lifters. Our Catalogs are over 80 pages. The clamps catalog is over 20 pages long. And we can add lifting eyes to plenty of our forklift attachments in the forklift catalog.

It seems more expensive to buy attachments vs going out and building a wood box. I don’t think it is. Not only is it faster at a rate that is around $500 per hour (crane + Operator + rigger) to just hook in, but the risk and the damage of injuries due to crane accidents are tremendously expensive. 8 figures is common. And when you consider that it’s rare that we sell anything that would last less that 20 years, the financial utility of what you are buying generates lofty returns in operations.