Crane Man Basket - Four Person - Crane Rescue Basket - Crane Gear

Man Basket

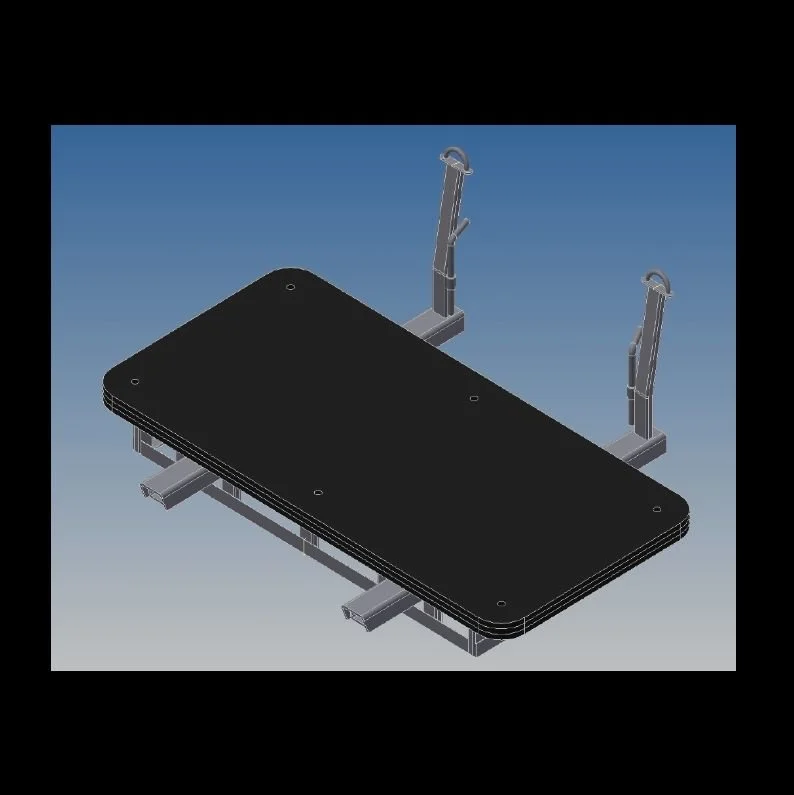

Crane Man Baskets or personnel baskets, are elevated work platforms designed to lift personnel to various heights for tasks such as maintenance, repairs, and construction. These platforms are typically suspended from cranes, aerial lifts, or forklifts, providing a secure and stable environment for workers to perform their duties at the basket’s rated capacity on the job site. The primary goal of suspended platforms is to ensure the safety of workers operating at heights, adhering to stringent OSHA requirements. These platforms are engineered to meet specific safety standards, and load capacity ensuring that they can handle the maximum intended load capacity while providing necessary safety features with the latest lifting technologies.

Crane Rescue Basket

Crane Rescue Baskets should be on every job site with work above a hoist, or below grade. Our man lifting baskets can be also used as a Crane Rescue Basket. We have an drop down end gate that can offers entrance to a 84 inches of length on the inside. The average rescue basket is 80.5 inches long. Get these powder coated in white and hang a medical cross on them showing what it’s for and be ready for this task at any time.

Safety Built In

Our Man Baskets designed to come with OSHA Compliance Built in. We meet ASME B30.23 for Personnel Hoisting for safe operation. There are four tie off locations in this unit to hook in your body harness. Overhead protection is built into the unit in case anything is dropped from overhead which will keep the workers safe. They come with a door that latches and swings in to prevent accidental opening. Handrails are around the entire perimeter and a grab rail is inside at the top to keep all of the fingers safe. The intermediate rail is well above the 21 “ requirement. And the welding is done by certified welders. The load bearing capacity of the unit is 1257 lbs for people and tools inside. This is our Working Load Limit. You will need to stay within this rated capacity to be compliant and to keep the workers safe.

Rigging will need to be supplied locally as the requirements differ from location to location. The bridle legs should have four for the platform. If a fifth is required for personnel, then that is where the local regulations are best served by buying it locally. We can supply it from the US for an additional charge. You’ll need to share your local codes to get the right bridle. We will make sure the lifting technologies used match your regulations.

OSHA Regulations

OSHA regulations are crucial in ensuring the safe use of suspended platforms. These standards cover various aspects of design, construction, and operation to protect workers and ensure a safe working environment.

Design and Construction: Personnel baskets or man lifting baskets must be designed and constructed to meet OSHA standards, including requirements for working load limits, safety devices, and personal protective equipment. This ensures that the platforms can safely support the maximum intended load and provide necessary safety features.

Operational Standards: The operation of suspended platforms must comply with OSHA standards, which include requirements for safety inspections, training, and certification.

Safety Regulations: Mandates the use of safety equipment and personal protective equipment to protect workers. This includes the use of guard rails, safety latches, and other safety devices to prevent falls and accidents. ASME B30.23 is very specific about how these Personnel baskets are constructed. We follow it to the letter.

Key OSHA regulations related to suspended platforms include:

1926.1431 - Hoisting Personnel Standard: This standard regulates the use of crane-suspended man baskets, ensuring they are used safely and effectively.

1926 Subpart CC - Cranes & Derricks in Construction: This standard covers the use of cranes and derricks in construction, including the safe use of suspended platforms.

1926.502 - Fall Protection: This standard mandates the use of fall protection equipment, including personal protective equipment and safety devices, to protect workers from falls.

Employers must ensure compliance with these regulations to provide a safe working environment for their employees.

Crane Gear Solutions

Our Crane Gear solutions are meticulously designed to deliver exceptional performance and reliability across a variety of applications. With a strong focus on precision engineering, our crane man baskets feature durability, safety components such as guardrails and non-slip flooring, and compliance with the standards for lifting personnel using cranes, including supplying an optional test weight for trial lifts. These attachments meet the highest standards of quality and durability, ensuring they stand up to the toughest tasks. Designed with North American usage and compliance perspective in mind, our crane gear solutions integrate seamlessly. Each basket is designed by a qualified engineer to ensure compliance with OSHA standards and safety requirements.

A test weight can be offered as built in with this unit. This will let you test the maximum load to 125%. The maximum load for the Four Person Basket is 1257 lbs. Having the test weight built in will enable you to conduct the test lift or proof test.

Here is a video to see this suspended platform with more details.

We also sell a two person platform of similar quality.

Should you consider a Rescue Platform - Blog on the topic.

Shipping Included

The price point as shown includes shipping, tariffs and customs fees. This is a door to door delivery that we can take care of for the total price shown. If you have multiple orders, the price per unit can drop significantly. Contact us for a quote as an Ex Works or for a larger order.

Man Basket

Crane Man Baskets or personnel baskets, are elevated work platforms designed to lift personnel to various heights for tasks such as maintenance, repairs, and construction. These platforms are typically suspended from cranes, aerial lifts, or forklifts, providing a secure and stable environment for workers to perform their duties at the basket’s rated capacity on the job site. The primary goal of suspended platforms is to ensure the safety of workers operating at heights, adhering to stringent OSHA requirements. These platforms are engineered to meet specific safety standards, and load capacity ensuring that they can handle the maximum intended load capacity while providing necessary safety features with the latest lifting technologies.

Crane Rescue Basket

Crane Rescue Baskets should be on every job site with work above a hoist, or below grade. Our man lifting baskets can be also used as a Crane Rescue Basket. We have an drop down end gate that can offers entrance to a 84 inches of length on the inside. The average rescue basket is 80.5 inches long. Get these powder coated in white and hang a medical cross on them showing what it’s for and be ready for this task at any time.

Safety Built In

Our Man Baskets designed to come with OSHA Compliance Built in. We meet ASME B30.23 for Personnel Hoisting for safe operation. There are four tie off locations in this unit to hook in your body harness. Overhead protection is built into the unit in case anything is dropped from overhead which will keep the workers safe. They come with a door that latches and swings in to prevent accidental opening. Handrails are around the entire perimeter and a grab rail is inside at the top to keep all of the fingers safe. The intermediate rail is well above the 21 “ requirement. And the welding is done by certified welders. The load bearing capacity of the unit is 1257 lbs for people and tools inside. This is our Working Load Limit. You will need to stay within this rated capacity to be compliant and to keep the workers safe.

Rigging will need to be supplied locally as the requirements differ from location to location. The bridle legs should have four for the platform. If a fifth is required for personnel, then that is where the local regulations are best served by buying it locally. We can supply it from the US for an additional charge. You’ll need to share your local codes to get the right bridle. We will make sure the lifting technologies used match your regulations.

OSHA Regulations

OSHA regulations are crucial in ensuring the safe use of suspended platforms. These standards cover various aspects of design, construction, and operation to protect workers and ensure a safe working environment.

Design and Construction: Personnel baskets or man lifting baskets must be designed and constructed to meet OSHA standards, including requirements for working load limits, safety devices, and personal protective equipment. This ensures that the platforms can safely support the maximum intended load and provide necessary safety features.

Operational Standards: The operation of suspended platforms must comply with OSHA standards, which include requirements for safety inspections, training, and certification.

Safety Regulations: Mandates the use of safety equipment and personal protective equipment to protect workers. This includes the use of guard rails, safety latches, and other safety devices to prevent falls and accidents. ASME B30.23 is very specific about how these Personnel baskets are constructed. We follow it to the letter.

Key OSHA regulations related to suspended platforms include:

1926.1431 - Hoisting Personnel Standard: This standard regulates the use of crane-suspended man baskets, ensuring they are used safely and effectively.

1926 Subpart CC - Cranes & Derricks in Construction: This standard covers the use of cranes and derricks in construction, including the safe use of suspended platforms.

1926.502 - Fall Protection: This standard mandates the use of fall protection equipment, including personal protective equipment and safety devices, to protect workers from falls.

Employers must ensure compliance with these regulations to provide a safe working environment for their employees.

Crane Gear Solutions

Our Crane Gear solutions are meticulously designed to deliver exceptional performance and reliability across a variety of applications. With a strong focus on precision engineering, our crane man baskets feature durability, safety components such as guardrails and non-slip flooring, and compliance with the standards for lifting personnel using cranes, including supplying an optional test weight for trial lifts. These attachments meet the highest standards of quality and durability, ensuring they stand up to the toughest tasks. Designed with North American usage and compliance perspective in mind, our crane gear solutions integrate seamlessly. Each basket is designed by a qualified engineer to ensure compliance with OSHA standards and safety requirements.

A test weight can be offered as built in with this unit. This will let you test the maximum load to 125%. The maximum load for the Four Person Basket is 1257 lbs. Having the test weight built in will enable you to conduct the test lift or proof test.

Here is a video to see this suspended platform with more details.

We also sell a two person platform of similar quality.

Should you consider a Rescue Platform - Blog on the topic.

Shipping Included

The price point as shown includes shipping, tariffs and customs fees. This is a door to door delivery that we can take care of for the total price shown. If you have multiple orders, the price per unit can drop significantly. Contact us for a quote as an Ex Works or for a larger order.

FAQ on Crane Man Baskets

What is the wind speed for a crane man basket?

The maximum wind speed is 20 mph. If it might gust over 20 mph, you cannot utilize a man basket with a crane.

Are man baskets OSHA approved?

The design criteria is set forth by OSHA. It is up to manufacturers and users to ensure the OSHA codes are complied with. OSHA does not inspect and approve baskets with a report or label.

What is the load test for a man basket?

The proof test or trial lift is to be 100 -125% of the intended load being held at the intended working radius for 0 to 5 minutes prior to occupancy by a human. OSHA 1926.1431h and ASME B30.23 offer guidance on this proof test topic. This is easy with a test weight.

How often should a man basket be inspected?

Prior to each use. After each load test with the test weight. Upon arriving on a job site. And annually.