ASME B30.20 and Load Container Inspection Criteria

If you haven’t become aware yet, a few months ago (May 2025) ASME B30.20 (Below the Hook) adopted “Load Containers” under their scope. I suspect it will be a while until the full application of this change is enforced in OSHA locations. The states that have more stringent laws are likely to wait to see what OSHA does so they don’t have to implement a rule twice. But in the mean time, there is a consideration Safety Directors, Riggers, Lift Directors, and Crane Operators should be aware of. It’s buried in the rules and it’s an issue you’ll want to be aware of. OSHA has already made it clear, they expect the inspection criteria of ASME B30.20 is followed in a letter of interpretation. That letter doesn’t cite a year of the referenced ASME. If the new ASME lays out new inspection criteria, is that the new standard everyone should already be following? Let’s take a look so you can decide.

OSHA 1926.251 is the rule that says all rigging items must be rated. You are required to have tags, and 125% as a minimum safety factor. And there is more. It’s vague. It is set up as a catch all rule. It’s so vague that people might tell themselves that it’s not about Below the Hook items. The Letters of Interpretation clear that up for us. In 2004 Jeff Moser wrote a letter that can be found there. In it he asks,

Question (2): Other than for slings, it appears that there are no inspection criteria for below-the-hook lifting devices in the OSHA regulations. Would I be in compliance with OSHA requirements if I followed ASME B30.20 for inspections of below-the-hook lifting devices?

Answer

Yes. Section 1926.251 does not address inspection criteria for below-the-hook lifting devices, except for slings used in conjunction with other material handling equipment.

Under the "General Duty Clause" (Section 5(a)(1)) of the Occupational Safety and Health Act, employers must:furnish to each of [its] employees employment... free from recognized hazards that are causing or are likely to cause death or serious physical harm...

The construction industry recognizes the necessity for inspections of below-the-hook lifting devices. An employer who follows ASME B.30.20, specifically sections 20-1.3.1 through 20-1.3.7 and 20-1.3.9 with respect to inspections for below-the-hook lifting devices (other than for slings), would be considered to be in compliance with OSHA requirements.

This letter citing ASME B30.20 as being included in the intent of 1926.251 removes all doubt with regard to the vague language and OSHA’s intentions. The citation of the inspection criteria as noted by 20-1.2.1 through 20-1.3.7 and 20-1.3.9 means that those “lifting accessories” (see OSHA 1926.251 (a).(4)) must be inspected to the ASME B30.20 standard. So what do we find there?

The inspections need to be done by a designated person. This person is going to fill out a report that is dated and laid out in 20-1.3.6 for records keeping. If it’s not rated, it certainly doesn’t meet the ASME or OSHA 1926.251. If it doesn’t have a “manufacturer” as noted in 1926.251 (a).(2) (i) & (ii) it doesn’t meet OSHA’s requirement. This deficiency would need to be escalated to a “Qualified Person” for them to remedy the matter. A qualified person in ASME B30.20 is listed as:

“possession of a recognized degree in an applicable field or certificate of professional standing, or who, by extensive knowledge…” .

The term “professional standing” indicates an engineer or a member of another related professional organization. This isn’t a qualified rigger deciding what can be done.

To break this down:

Everything needs a rating.

If it doesn’t have a rating from a manufacturer, a qualified person would need to determine the solution/repair.

The rigger or operator isn’t in the position to sign off on “repairs” which would include the tagging or retagging of a load container. In most cases, an engineer is going to want quite a few details to assign a rating and you’ll need to perform a load test that will be conducted by the engineer. (See ASME B30.20-1.3.9.1 as cited by the OSHA letter to Moser)

These are the currently the standards we are to be working to. There isn’t a need for intervention by OSHA. They can expect this of managers and the field staff today. The only question is, will they? I suspect OSHA is still digesting this change. For me, it’s easy to point to existing rules that suggest quite clearly that all load containers that don’t have a rating, or a manufacturer, need to be moved out of use in construction. They cannot be lifted by a crane unless they are in a rated load container. There are other issues like “Lack of bond between surface materials and metal backing.” They are looking for a bolt or weldment and steel as the material doing the structural supporting. I would suggest getting the ASME and looking at your “lifters” and see how they comply with the inspection criteria found in the ASME. There is a BTH-1 design document as well. This is not cited by OSHA at this time. But it does help understand the inspection criteria OSHA has cited in the Letter to Moser. Or, the ASME requires instructions of the manufacturer in the OSHA cited 20-1.3.7. If the lifter was homemade, the manufacturer instructions will not be in place. Operationally, how do you know where to put the slings on a lifter if the instructions or labels are missing?

If you don’t have the inspection records, you are in violation of OSHA 1926.251. If your inspection document doesn’t match ASME B30.20 they have made it clear it’s citable. Homemade boxes and other load containers not manufactured and rated are not going to comply with the rules as they exist today. There just isn’t a way around the problems that come with homemade lifters. OSHA 1926.251 and OSHA’s citation of sections of the ASME that require a manufacturer ends the debate. A missing tag, just like on a sling, or a missing instructions and it fails the inspection criteria. If you are a Qualified Rigger, Lift Director, Crane Operator, or a Safety Manager, it’s probably time to take a look at this issue. If you are the person signing off on these Periodic Inspection Reports, or hooking up to lifters that don't have a tag or Inspection Reports, you are taking unnecessary risks. Treat it just like you would with a sling without a tag or a crane without a manual. It's out of service until someone else puts their name on it.

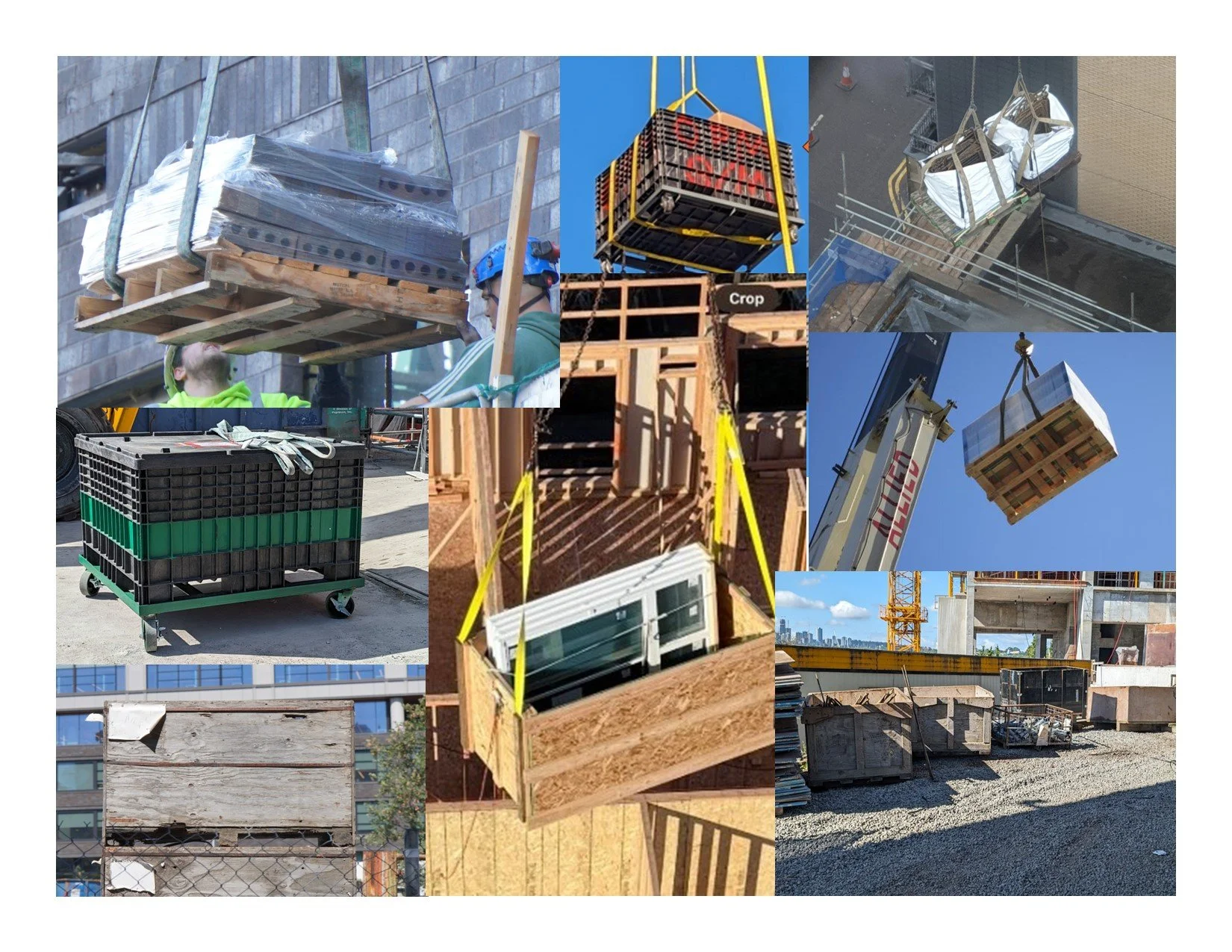

Common lifters we find in the field that would not match ASME B30.20 or OSHA 1926.251. None of these lifts should happen with a crane.